Add to Cart

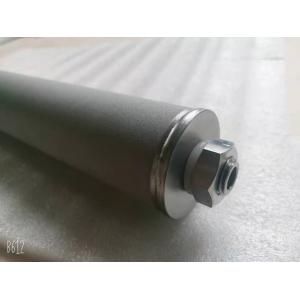

Sintered Stainless Steel Filter Plate Gas Purification Desalination Filtration

1. Overview

a.stainless steel powder sintering filter element

The stainless steel powder sintered filter element is made of ultrafine stainless steel powder sintered at high temperature. By selecting the powder particle size and process parameters, the pore size and distribution can be adjusted. It is especially suitable for replacing the titanium rod filter element in the decarburization process of pharmaceutical industry.

b.Main technical parameters

Filter aperture: / 1/3/5 / (0.45/50/80/100 (microns)

Material of filter element: 316 powder

Operating temperature: 0~450℃

Diameter: 50, 60, 65 (mm)

c.The main features

1.1. Controllable pore size and porosity, high filtration accuracy

2.2. Good permeability and small initial pressure difference

3.3. Corrosion resistance, can be used in highly corrosive environment

4.4. High mechanical strength, good stability, can work under high pressure difference

5.5. High temperature resistance

6.6. Renewable and long service life

d.Typical application

1.1. High temperature steam and gas filtration

2.2. Filtration of oil slurry and other petrochemical products

3.3. Filtration and recovery of solid catalysts

4.4. Ozone disinfecting water filtration in food production process

5.5. Filtration of chemically complex liquids

6.6. Filtration of liquid and gas under high temperature and pressure

e.Features:

1.) Excellent filtration performance (1-100 micro pore size)

2. )Shape stability and high strength of elements

3.) High temperature resistance (working under high temperature environment <900 °C)

4.) High corrosion resistance

5.) High impact and alternating load

6. )Better permeability and excellent separation

7. )Good backwash, easy to recover elements

2.Application:

Widely used in petrochemical industry, chemistry, fine chemical industry, coal chemical industry, food and beverage, nuclear power, shipbuilding, automobile manufacturing and other industries

1. )Catalyst filtration

2.) Filter liquids and gases

3.) Produce a filter for recovering mother liquor from PAT

4.) Filters for food and drink

5.) Boiling turning lathe

6.) The liquid flushes the foam of the tank

7.) Fire fighting and isolation

8.) Balance and damp airflow

9.) Sensor probe protection

10.) Filter and mute pneumatic equipment

11)Pulverized coal processing

12. )Gas homogenization and gas channels in the powder industry

13.) Other

3.Performance description

1) Diameter: 18mm, 20mm,25mm, 30mm, 40mm, 50mm, 55mm, 60mm, 70mm,75mm, 80mm

2)Length: Max 1200mm/pcs

3)Micro pore size(Filter precision): 1um-100um

4)Thickness: 2-3mm

5) Accept special customization

4.Features of stainless steel sintered porous materials:

Stainless steel sintered porous material has excellent corrosion resistance, oxidation resistance, wear resistance and mechanical properties.

| Material | Filter Rating | Porosity | Penetrability | Working pressure | Operating temperature | Shape | specific surface area |

| 304,304L,316, 316LStainless steel powder | 0.5um-100um | 25-45% | 3-1300M³/M²hKPa | 3.0MPa | 600℃ | Round Disc,SheetTube, Round,Bar,cap. | 10-40cm²/cm³ |

5. Products view